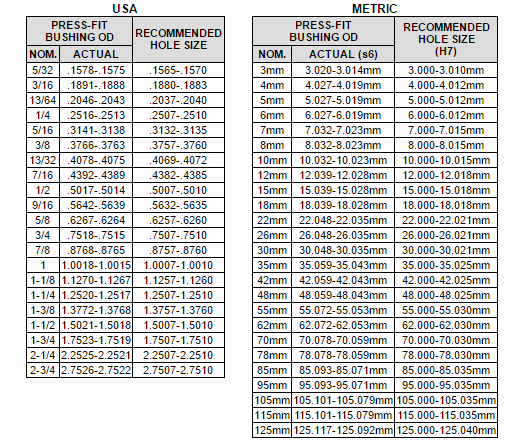

Bearing Press Fit Tolerance Chart

Upper lower upper lower.

Bearing press fit tolerance chart. Should be used. Wobble or shake between mating parts noticed only on parts with short bearing length. Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards. Easily possible possible impossible easily possible h7 h8 g7 js6 j6 generally impossible k6 m6 or n6 h6 70424 f c 24pp uk qxd 6 27 06 10 31 am page 5 4 fits and clearances pocket guide fits between radial bearings and.

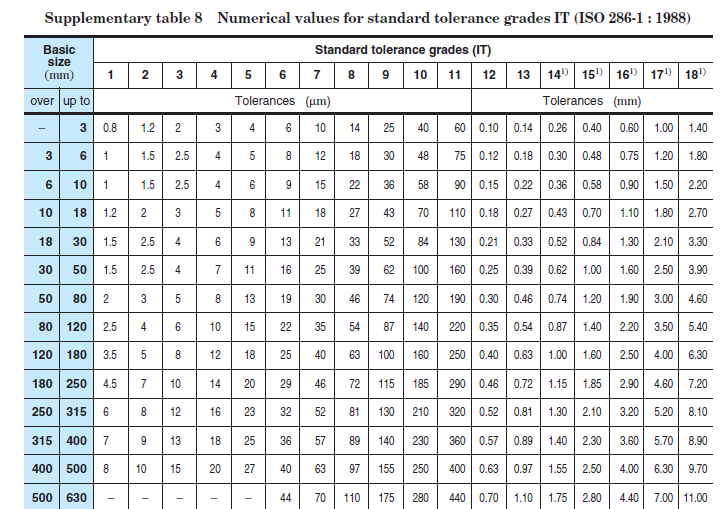

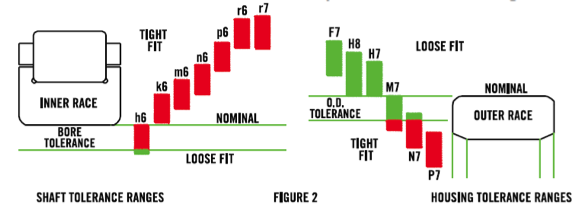

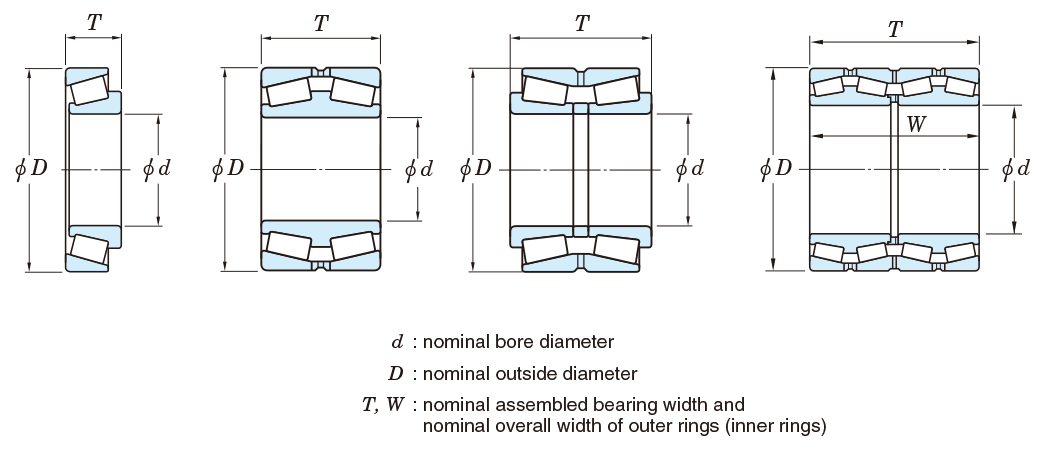

Class iii medium fit running fits under 600 r p m and journal pressures under 600 lbs sqin and for sliding fits. Figure 2 is a graphic representation of the relationship to the various fits with the bearing bore and o d. Middle high speed light or normal load. The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection.

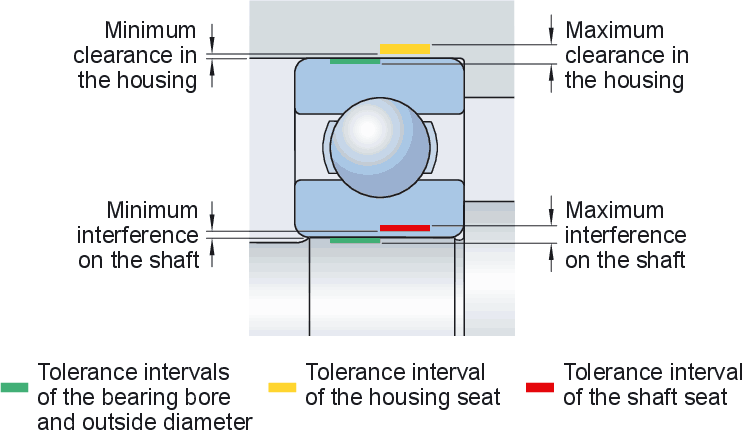

Notice on the left the f6 fit is a very loose fit so the block is dropped away from the lowest tolerance line. With a tight fit the bore of the inner ring of the bearing is slightly smaller than the outer shaft diameter. If a different grade of bearing is used this will affect recommended dimensions of mating components. Bushings are available in standard sizes with both inside and outside diameters surfaces finished and are commonly available in many sizes.

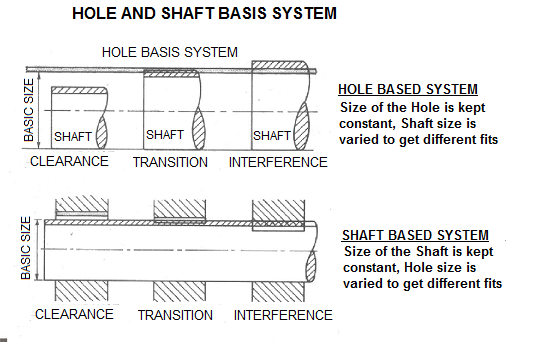

All fits are based on the normal tolerances for bearing bores and o d s. As both bearing bore size and o d. 0 5 1 2 5 2 5. A line to line assembly is when the bore of the inner ring of the bearing and the outer diameter of the shaft are the same.

Class iv transitional fit snug closest fit which can be assembled by hand and necessitates work of considerable precision. Rotating inner ring load. M7 k7 possible axial displacement of outer js7 j7 ring is necessary. Press fit or shrink fit bushing design and installation is a common method of retaining bearings by use of interference between the bushing and the bushing hole.

It is assumed that bearings used are abec 5 tolerance 0 0002 inch for bore and o d. In contrast the p6 fit on the other end would always be in interference with the shaft. The following table shows recommended shaft and housing sizes and tolerances for different applications. Increase their normal tolerances increase as does the absolute tolerances for the shaft o d s and housing bores.

Strict tolerances should be used for fitting. Gyro rotors air cleaners electric tools encoders. The tables in this section provide information about bearing tolerances seat tolerances and resultant fits these should enable you to determine easily the maximum and minimum values of fits when using iso tolerance classes for bearing seats and bearings with normal tolerances for the bore and outside diameter. The schematic representation of the fit is also drawn.