Running Fit Tolerance

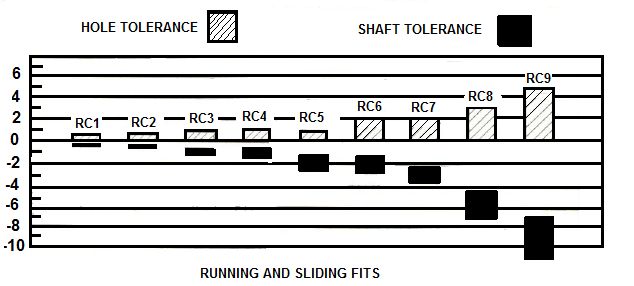

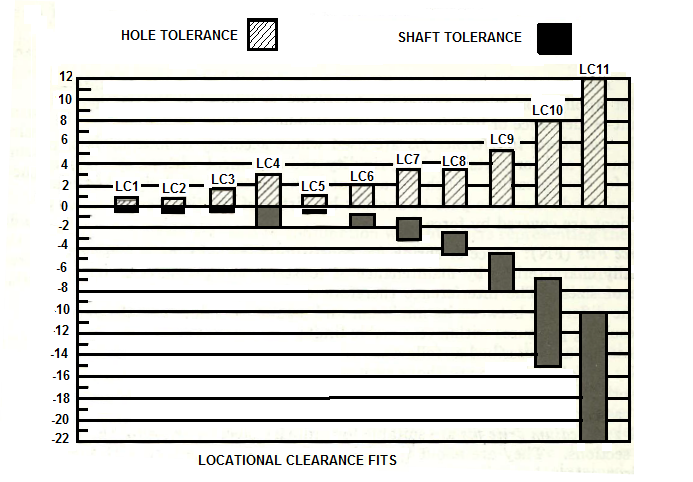

Graphical representation of ansi b4 1 1967 running and sliding fits table running and sliding limits and fits for cylindrical parts ansi b4 1 1967 r1987.

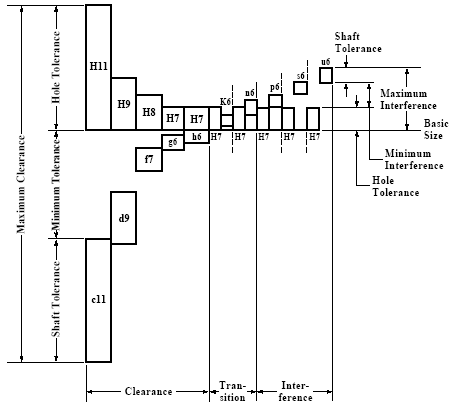

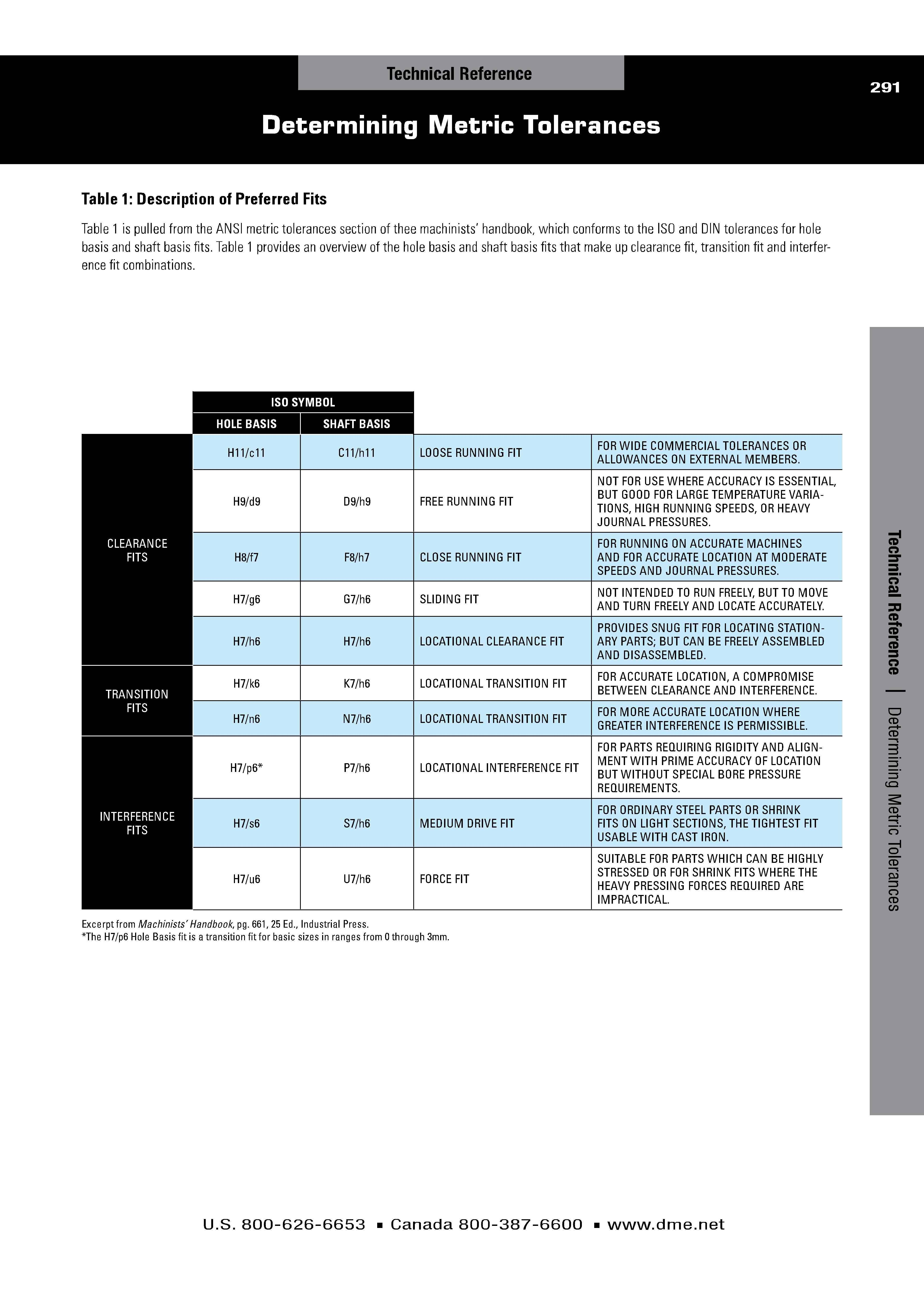

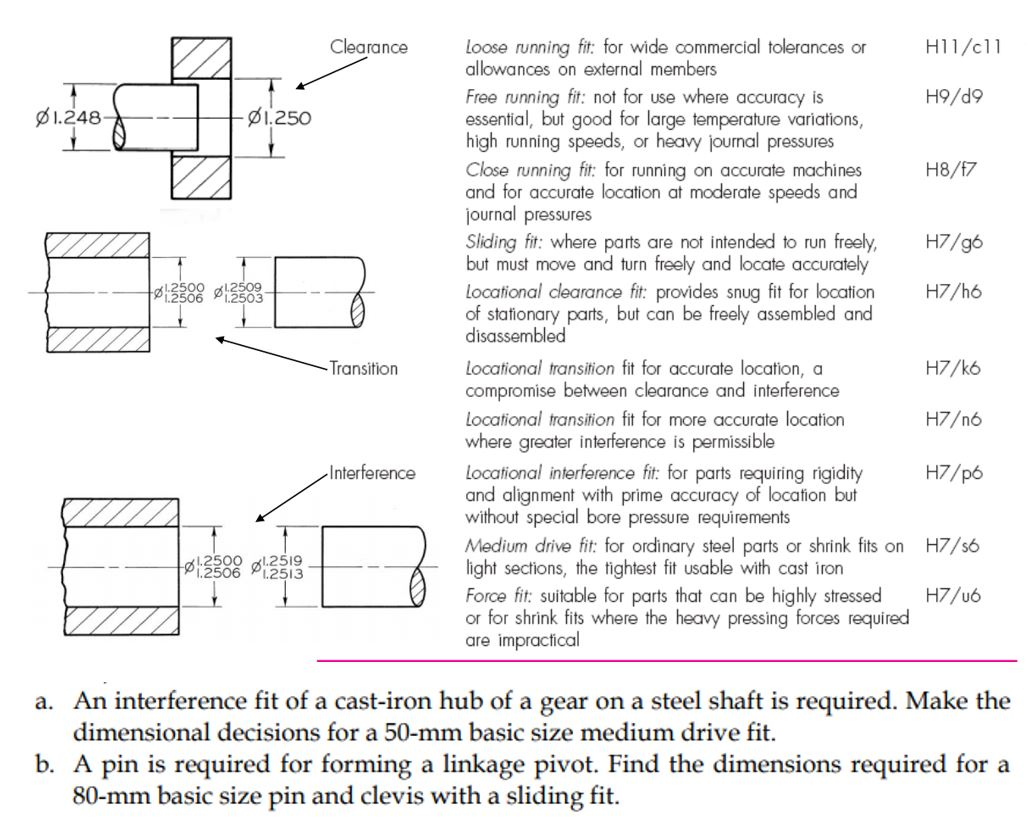

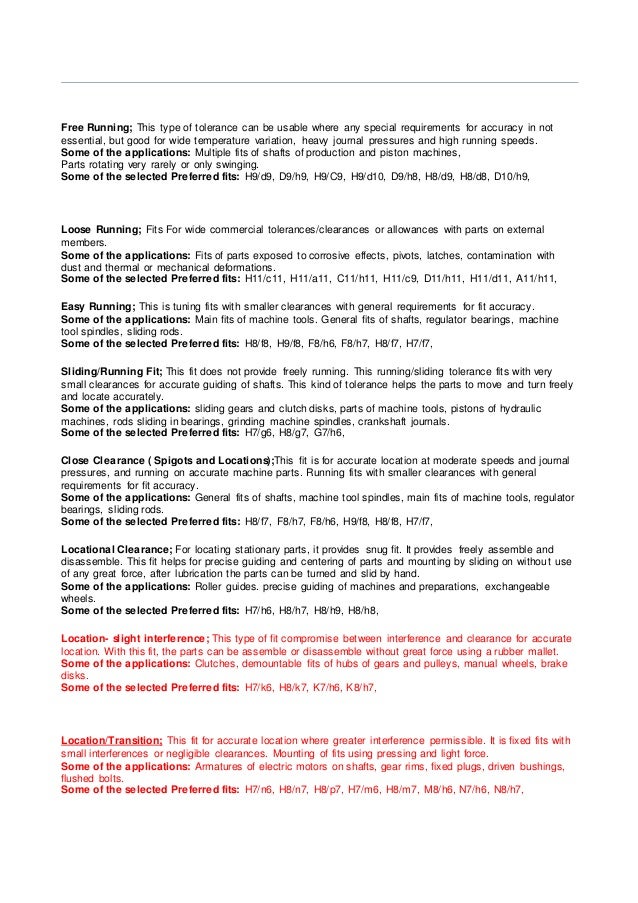

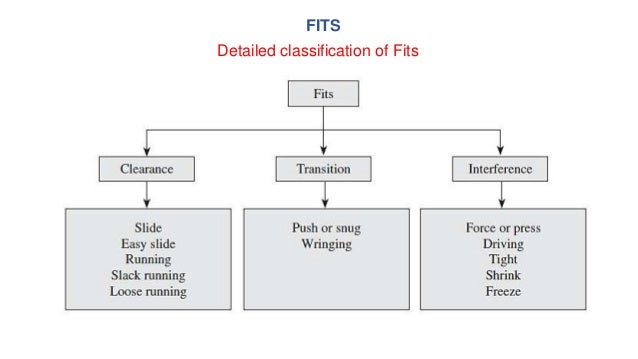

Running fit tolerance. Loose running fit for wide commercial tolerances or allowances on external members. Loose running fit for wide commercial tolerances or allowances on external members. Fits examples h11 c11 slack running fit used to give flexibility under load easy assembly or a close fit at elevated temperatures. Bases of tolerances deviations and fits bs en 20286 2.

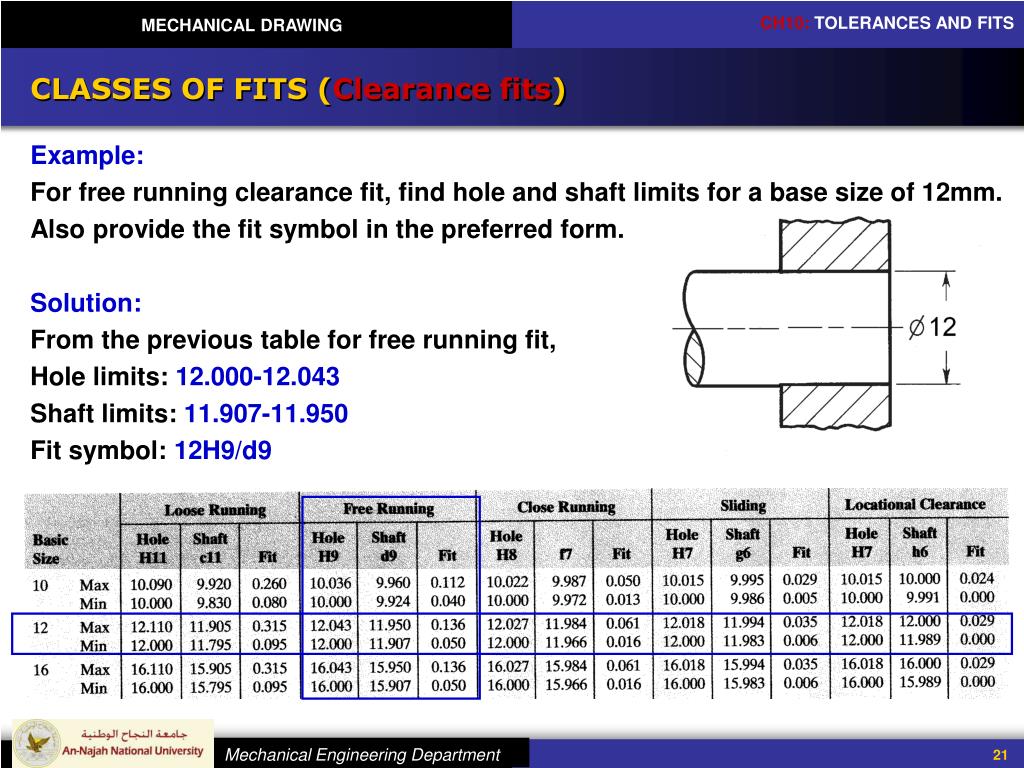

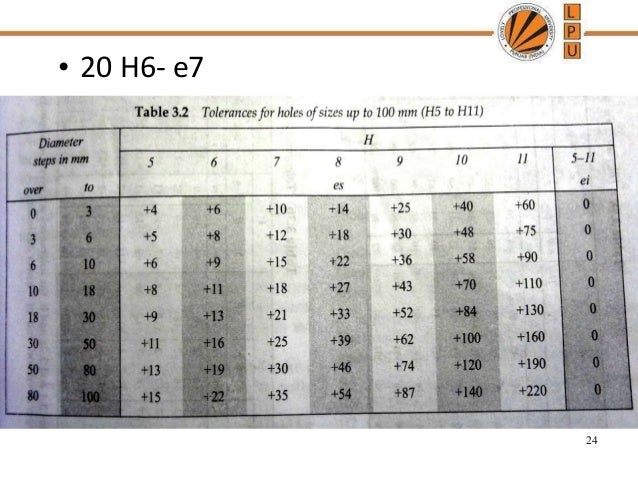

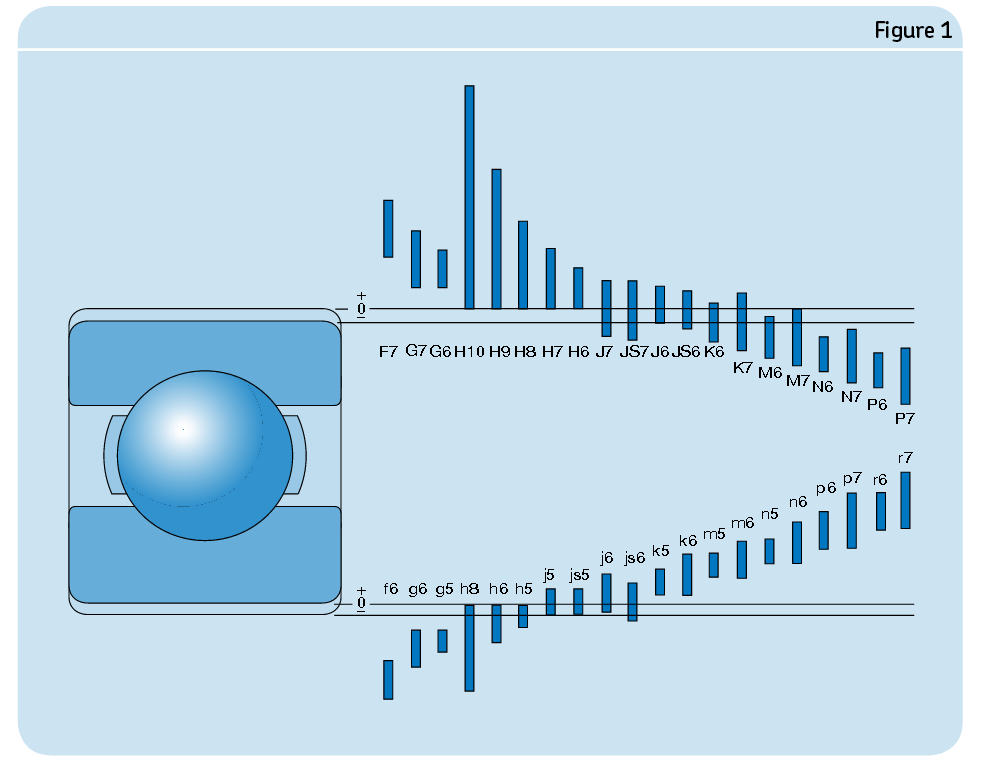

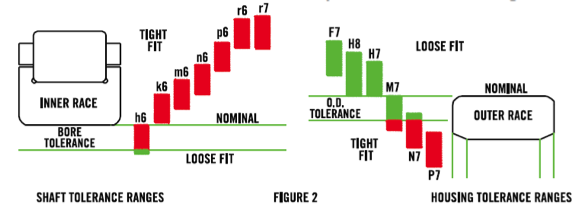

Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards. Tables of standard tolerance grades and limit deviations for holes and shafts notes. Based on standard tolerances and limit deviations in accordance with iso 286. The schematic representation of the fit is also drawn.

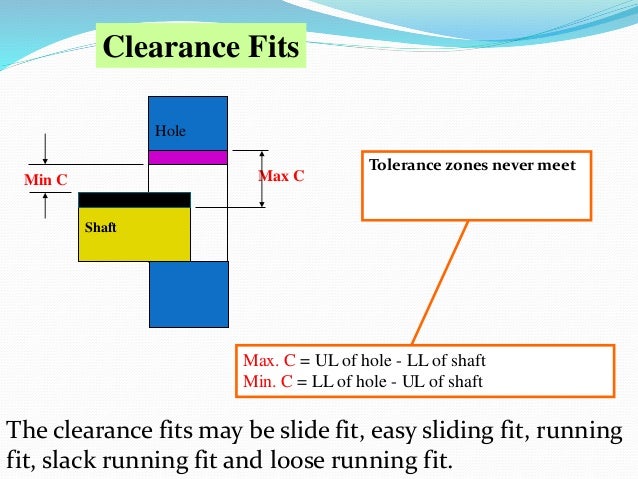

Class ii free fit running fits with speeds of 600 r p m. The tolerance of size is normally defined as the difference between the upper and lower dimensions. Tolerances and covers a range from loose clearance to heavy interference fits. A class rc 5 fit is to be used in assembling a mating hole and shaft of 2 inch nominal diameter this class of fit was selected because the application required intended for higher running speeds or heavy journal pressures see description of fits rc 5.

Wobble or shake between mating. Iso system of limits and fits. Idler gear on. Free running fit not for use where accuracy is essential but good for large temperature variations high running speeds or heavy journal pressures.

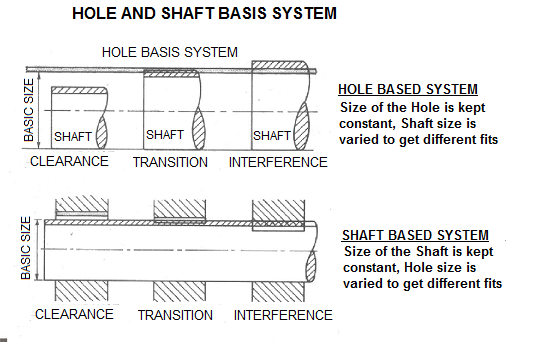

Close running fit for running on accurate machines and for accurate location at. Use of standard fit tables. A fit which may provide either a clearance or interference between the shaft and hole when assembled depending on the actual sizes of the shaft and hole is known as transition fit. Or over and journal pressures of 500 lbs sqin or over.

It may be noted that in a transition fit the tolerance zone of shaft and hole overlap completely or partially. Free running fit not for use where accuracy is essential but good for large temperature variations high running speeds or heavy journal pressures. The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection. Minimum hole 2 inches.

With this fits the parts with great clearances with having great tolerances. Iso system of limits and fits. Wobble or shake between mating parts very slight. Engine exhaust valve in guide h9 d10 loose running fit used for gland seals loose pulleys and very large bearings.

Maximum hole 2 0 0018 2 0018. Class iii medium fit running fits under 600 r p m and journal pressures under 600 lbs sqin and for sliding fits. Fits and tolerances calculator calculate fits and tolerances for shafts and holes here.