Running Fit Tolerance Metric

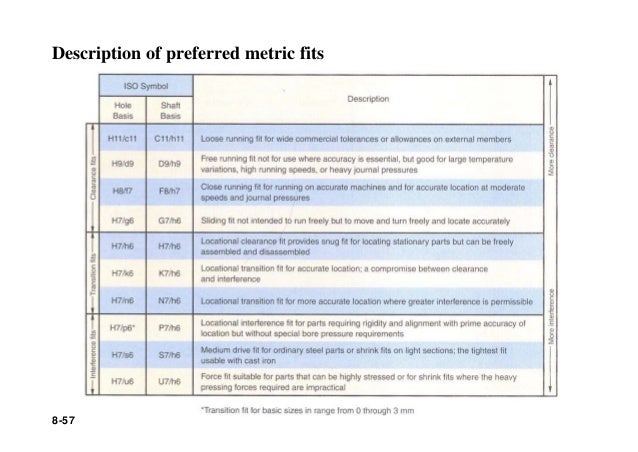

The aim is to help the designer to choose the appropriate and preferred fit tacking into account the standard uses for mechanical applications.

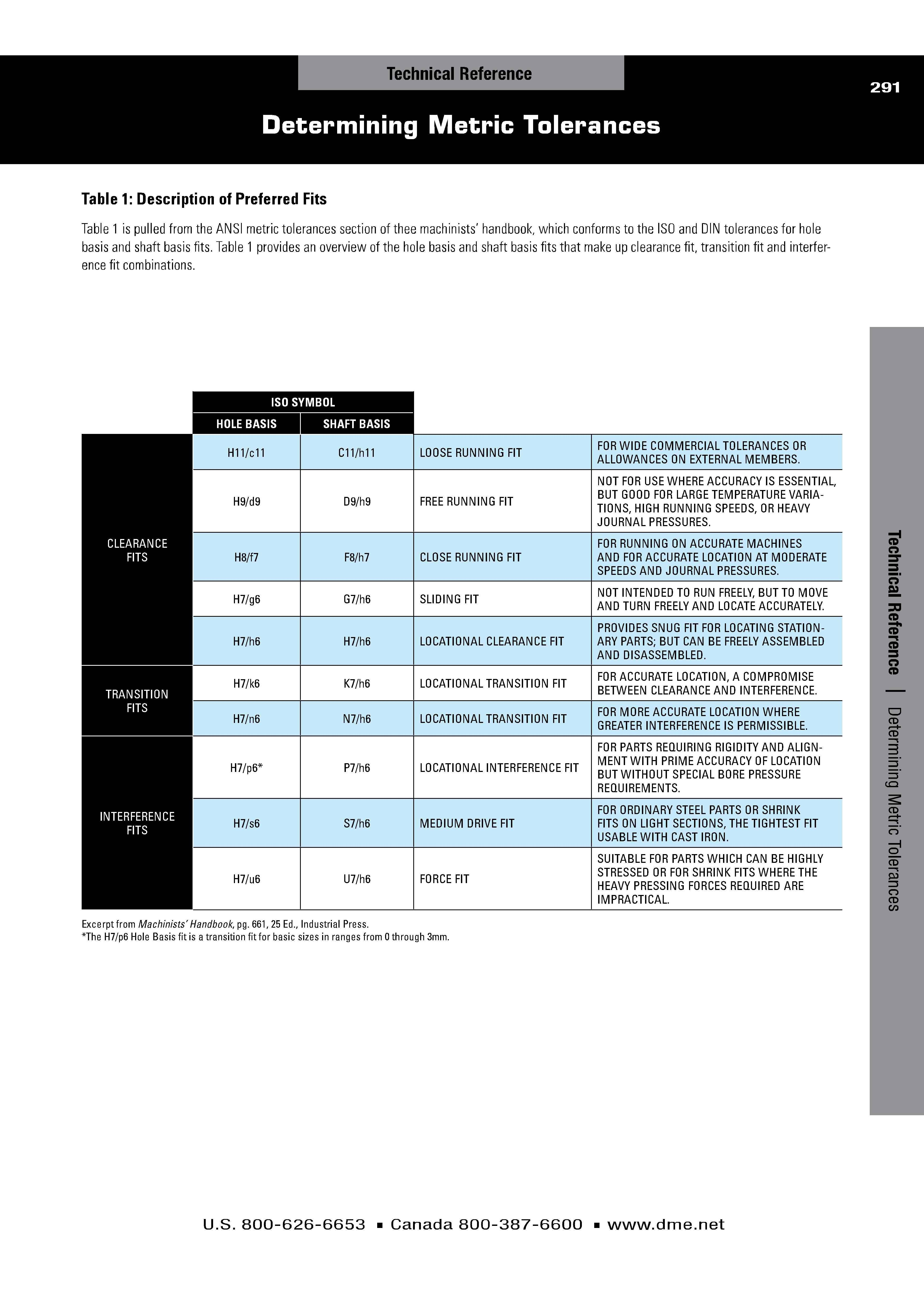

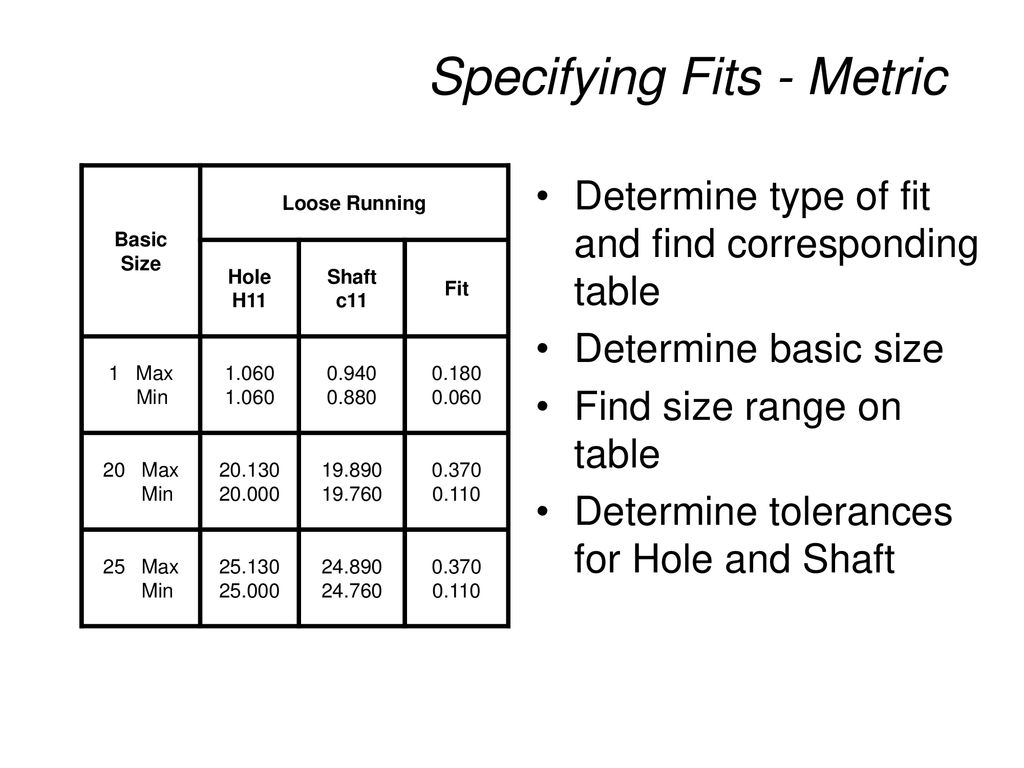

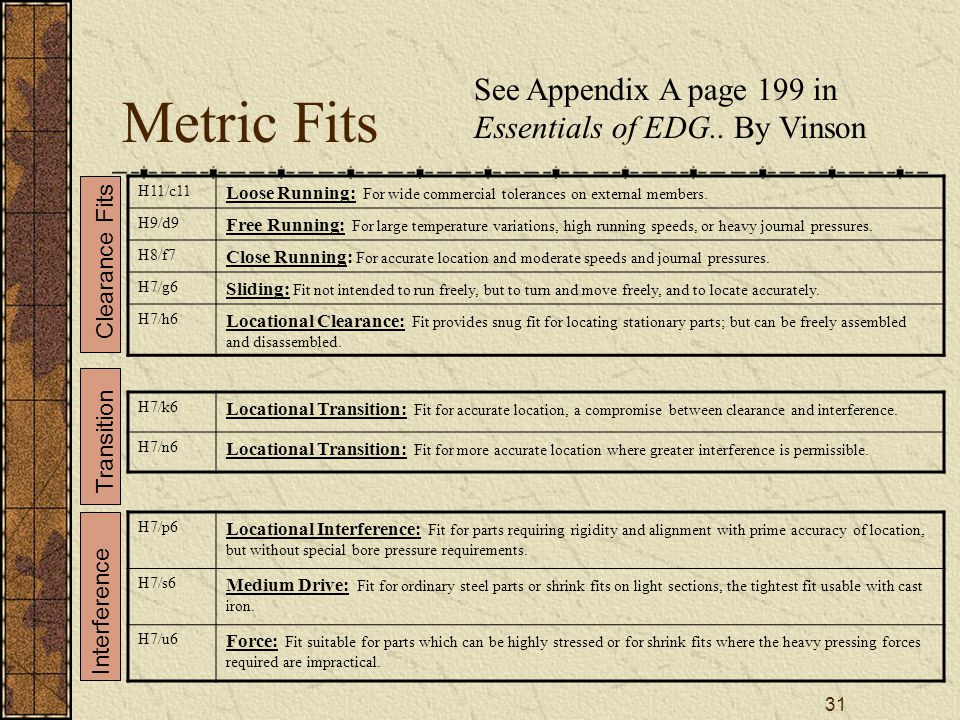

Running fit tolerance metric. Free running fit not for use where accuracy is essential but good for large temperature variations high running speeds or heavy journal pressures. Fits examples h11 c11 slack running fit used to give flexibility under load easy assembly or a close fit at elevated temperatures. Loose running fits exposed to effects of corrosion contamination by dust and thermal or mechanical deformations. Mechanical tolerance chart data.

This section reports a summary of the available information that can be found on technical literature about the fit tolerance between shafts and holes. This kind of fits are intended for use where wide commercial tolerances may be required on the shaft. Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards. Idler gear on.

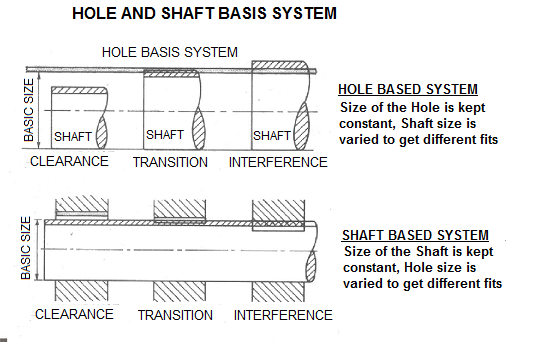

Hole based fits should be preferred. The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection. The schematic representation of the fit is also drawn. The video covers the basics of fits and tolerances in an easy to understand way with visual examples.

25 h11 c11 fits are either based on the hole feature or the shaft feature. Preferred mechanical tolerances metric iso 286. The following defines the preferred tolerance basis for hole and shaft per. Bases of tolerances deviations and fits bs en 20286 2.

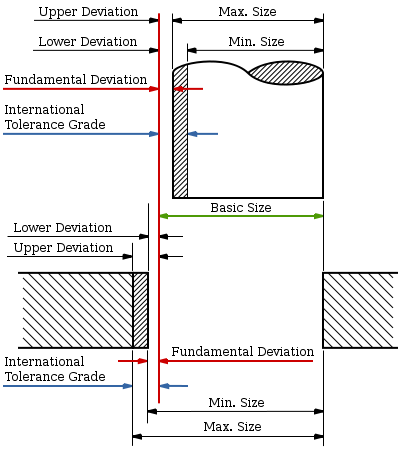

Iso system of limits and fits. Tables of standard tolerance grades and limit deviations for holes and shafts notes. In engineering terms the fit is the clearance between two mating parts and the size of this clearance determines whether the parts can at one end of the spectrum move or rotate independently from each other or at the other end are temporarily or permanently joined. Iso and ansi standards the following tables report the preferred metric fits and tolerances for hole.

25 h11 c11 or separated with a dash ex. The tolerance of size is normally defined as the difference between the upper and lower dimensions. 25 h11 or 25 c11 a fit is defined by the basic size followed by the tolerance of each component. Free running fit not for use where accuracy is essential but good for large temperature variations high running speeds or heavy journal pressures.

With this fits the parts with great clearances with having great tolerances. Engine exhaust valve in guide h9 d10 loose running fit used for gland seals loose pulleys and very large bearings. Loose running fit for wide commercial tolerances or allowances on external members. Iso system of limits and fits.

Tolerances and covers a range from loose clearance to heavy interference fits.