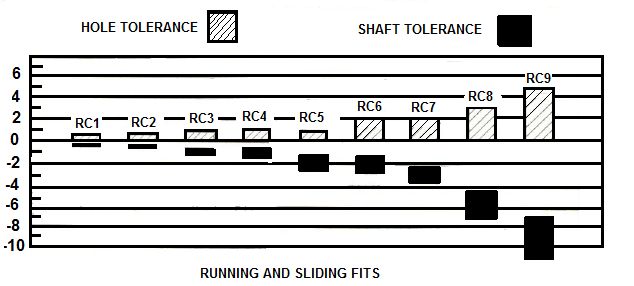

Running Fit Tolerance Chart

Wobble or shake between mating parts very slight.

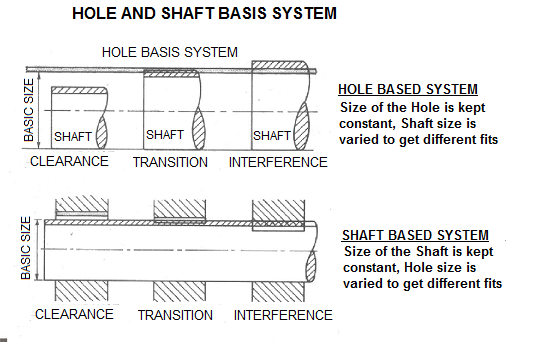

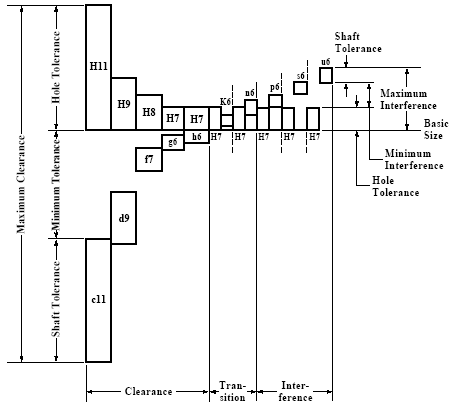

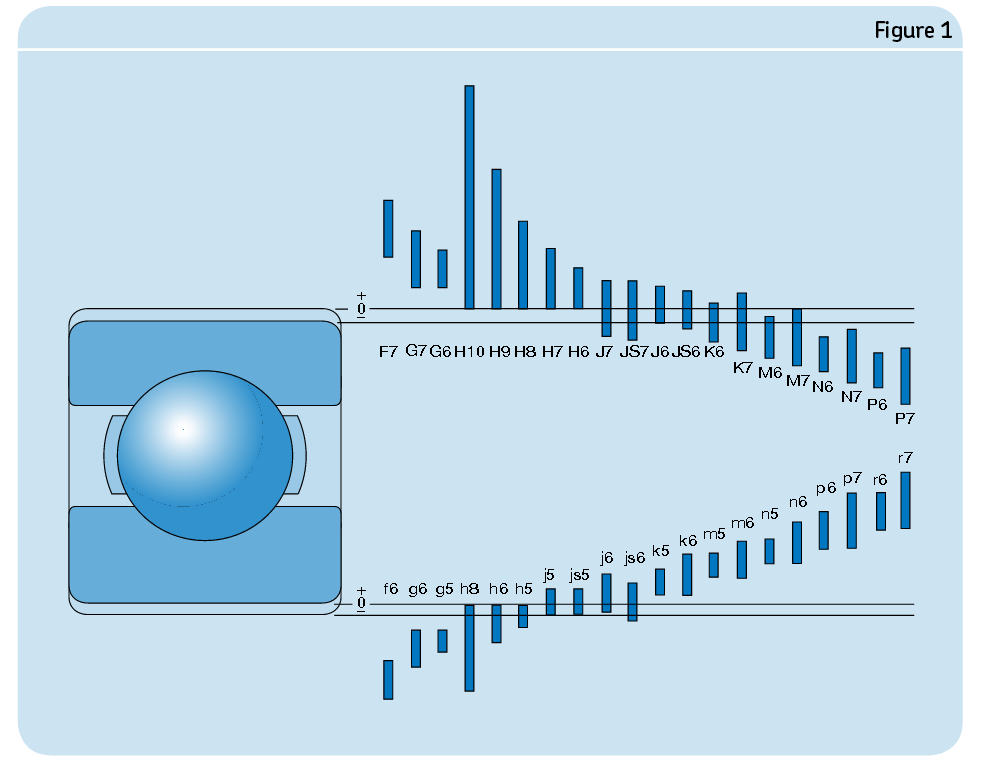

Running fit tolerance chart. Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards. With this fits the parts with great clearances with having great tolerances. Fit is defined as the degree of freedom of tightness between the mating parts in an assembly process it is also defined as the relationship between the hole and the shaft during the assembly is called fit in this article we are going to discuss different types of fits in a detailed way. The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection.

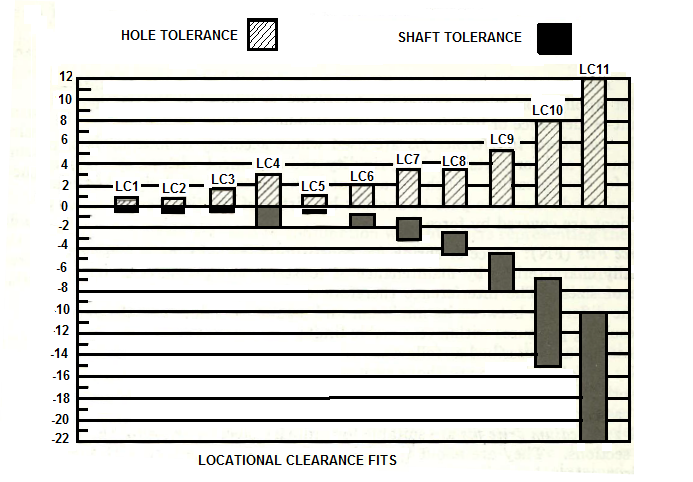

Class iii medium fit running fits under 600 r p m and journal pressures under 600 lbs sqin and for sliding fits. The schematic representation of the fit is also drawn. Some of the applications. H9 d9 d9 h9 h9 c9 h9.

The aim is to help the designer to choose the appropriate and preferred fit tacking into account the standard uses for mechanical applications. Iso and ansi standards the following tables report the preferred metric fits and tolerances for hole. H9 e9 h8 e8 h7 e7 e9 h9 e8 h8 e8 h7 running fits with greater clearances without any special requirements for fit accuracy main fits of machine tools. Free running fit not for use where accuracy is essential but good for large temperature variations high running speeds or heavy journal pressures.

A class rc 5 fit is to be used in assembling a mating hole and shaft of 2 inch nominal diameter this class of fit was selected because the application required intended for higher running speeds or heavy journal pressures see description of fits rc 5. Maximum hole 2 0 0018 2 0018. Engineering fits are generally used as part of geometric dimensioning and tolerancing when a part or assembly is designed. This kind of fits are intended for use where wide commercial tolerances may be required on the shaft.

The various parameters that can be included are maximum interference minimum interference maximum. Multiple fits of shafts of production and piston machines parts rotating very rarely or only swinging. Loose running fit for wide commercial tolerances or allowances on external members. Use of standard fit tables.

This type of tolerance can be usable where any special requirements for accuracy in not essential but good for wide temperature variation heavy journal pressures and high running speeds. Multiple fits of shafts of production and piston machines parts rotating very rarely or only swinging. Class ii free fit running fits with speeds of 600 r p m. Part will turn and slide freely.

Minimum hole 2 inches. Or over and journal pressures of 500 lbs sqin or over. Some of the selected preferred fits. In engineering terms the fit is the clearance between two mating parts and the size of this clearance determines whether the parts can at one end of the spectrum move or rotate independently from each other or at the other end are temporarily or permanently joined.