Push To Connect Air Fittings Leaking

Good mate of mine down here builds laser profiling machines.

Push to connect air fittings leaking. Service calls for gas or water leaks jumped 10 fold. If the fitting is leaking it is very unlikely the leak has sprung because of a manufacturer defect or faulty product design. Probably 200 fittings per machine. Most common issue is brittle o ring happens over time as rubber hardens and thus not able to make perfect seal causing air leaks.

These composite fittings are constructed with nickel plated brass resin and polyoxymethylene plastic components. Quick connect fittings have a simple but powerful design. I had one leak but it was a major leak and was because i didnt push the line in far enough it was a big enough leak you knew exactly what it was. They are full of push in fittings for air oxy nitrogen cooling water and pressure sensing.

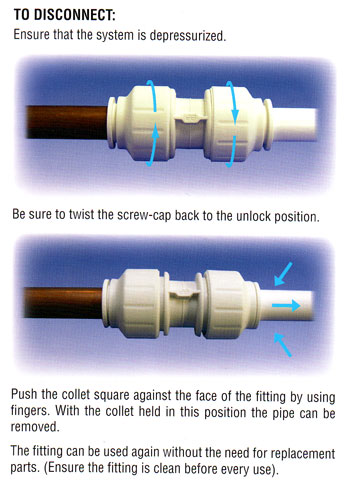

These fittings use an internal collet and an external push button to connect quickly and effortlessly creating a leak free connection. He started off with camozzi but latter switched to plastic smc or festo. Push to connect pneumatic tubing connections fittings are a continual source of compressed air leaks and production interruptions probably seventy five to eighty percent of push to connect type tubing fittings use flexible tubing selected for. Jump to latest follow 1 14 of 14 posts.

Simply just pushed it in all the way pulled back to set it in place and 0 leaks. Over many years of reviewing industrial compressed air production machinery of many types and styles there is one common thread or complaint. Airline sizes with 1 8 1 4 and 3 8 npt fittings if applicable. Just the nickel plated or brass push to connect style fittings maybe things have changed since the late 90 s here is a pretty good pic showing what i have used in the past i have never liked the compression fittings as after you snug them.

Please see product page for details. The majority of leaking quick connect fitting leaks are caused by a damaged o ring improper installation eroded tubing or too much torque placed on the t. Viair s push to connect fittings come in 1 8 1 4 and 3 8 o d. Leak free seals are easily achieved using dot approved push to connect air brake fittings by easily pushing the fitting onto the tube or hose.

Suitable for polyurethane or nylon tubing our push to connect air fittings guarantee leak free and secure connections for all of your pneumatic applications. The majority of leaking quick connect fitting leaks are caused by a damaged o ring improper installation eroded tubing or too much torque placed on the tubing. Just find the right size o. Ive always had leaks with compression fittings and cant reuse them like ptc.