Press Fit Hole Size

Design for press and slip fit of dowel pins used for alignment of mating parts utilizing gd t tolerancing methods.

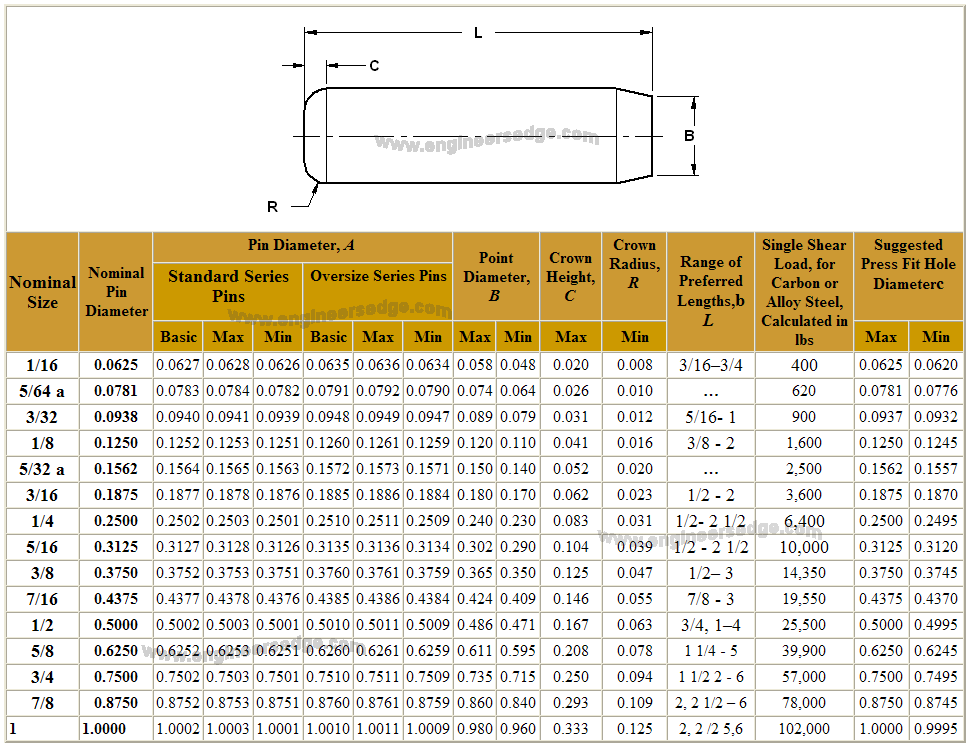

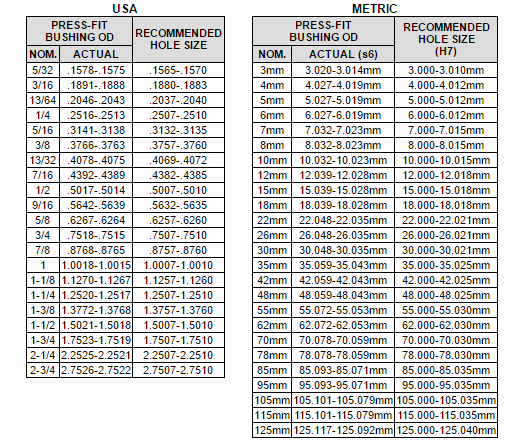

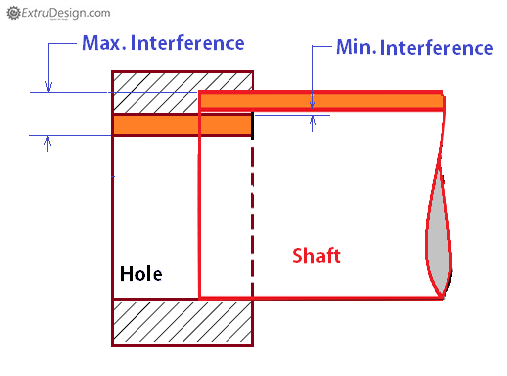

Press fit hole size. With a suggested minimum hole size of 0 4995 inches we end up with 0 0007 inches of diametrical interference. In addition designers need to need to know the exact amount of interference between the parts i e the difference in size between the inserted part and the hole and the length of the press fit. In calculating holding force for press fits also think about the press size needed for assembly. Where an interference fit is required as opposed to a sliding or clearance fit the dowel must be precision ground and the hole must be reamed.

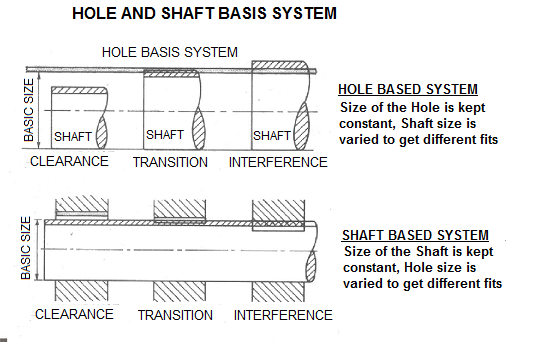

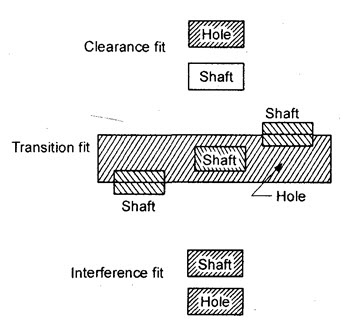

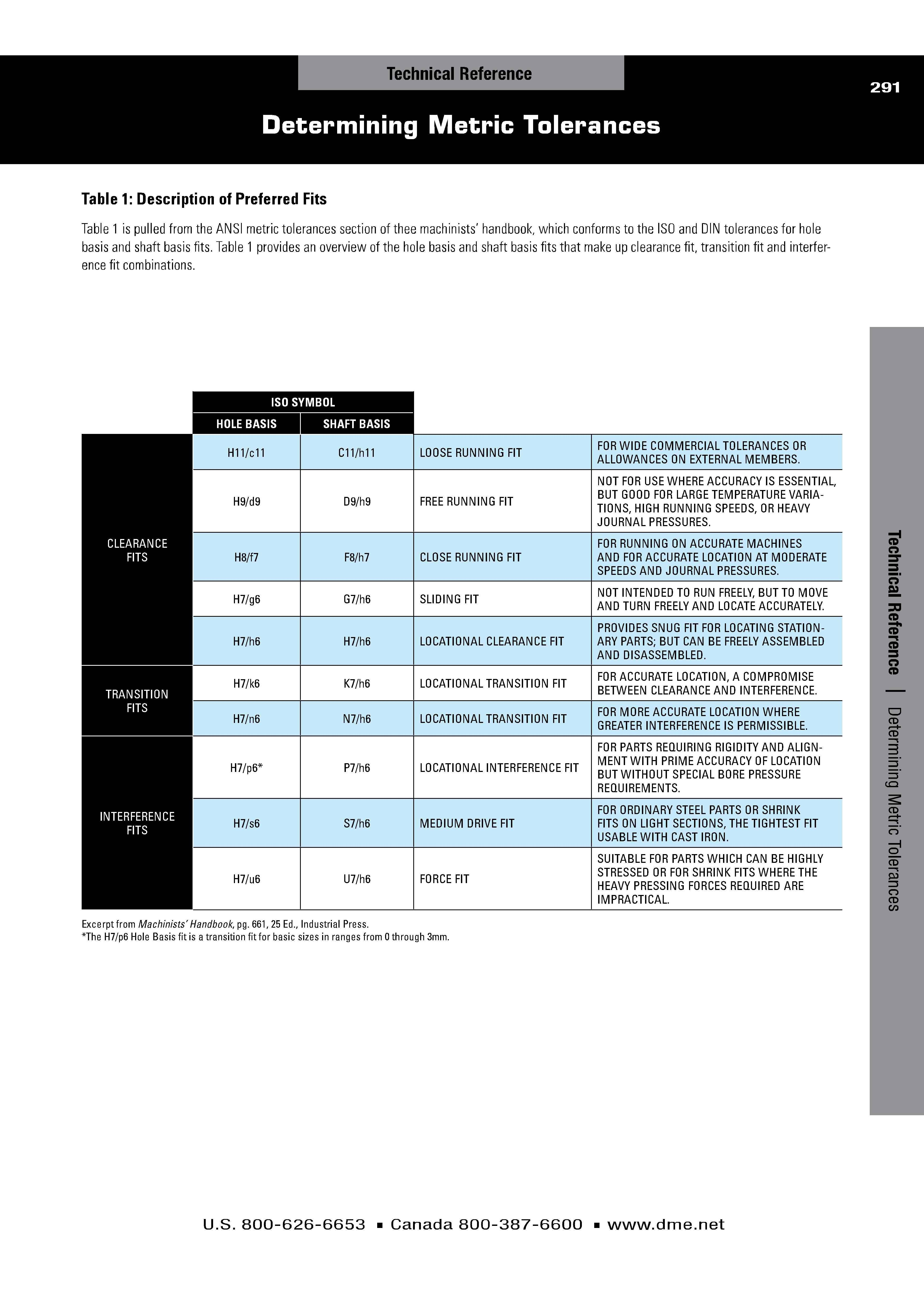

An interference fit also known as a press fit or friction fit is a form of fastening between two tight fitting mating parts that produces a joint which is held together by friction after the parts are pushed together. Critical components that must not sustain. Should these design guideline be inadequate reference the charts given within the hole shaft tolerance pages. The relationship between the diameter of the pin and the diameter of the hole must take into account the ductility of the dowel and the hole material and will vary more accordingly to this factor than according to the size of the dowel itself.

Depending on the amount of interference parts may be joined using a tap from a hammer or pressed together using a hydraulic ram. Among the biggest users of press fits are manufacturers that assemble automotive medical white goods solar energy and consumer products. The schematic representation of the fit is also drawn. Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards.

Hole size for press fit steel pin into aluminum ornerynorsk industrial 23 apr 10 11 18 given the correct press and installation driver a 0 005 pre install press fit on a 125 pin is probably going to swage material thereby not giving you a true 005 interference fit. The parts can be assembled by hand. The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection. Review your design to determine if you have similar application requirements.

This standard defines preferred limits and fits for press fits applications of non threaded cylindrical features preferred tolerances limits fits calculator rc lts this calculator will determine the preferred size and limit tolerances for running or sliding to interference locational fits per ansi b 4 1. Clearance fits have limits of the size prescribed so that a clearance always results in a positive allowance or air space is left between mating parts. The difference between the size of the hole and the size of the shaft is defined as clearance. Clearance fit is of two kinds namely sliding and running fits.

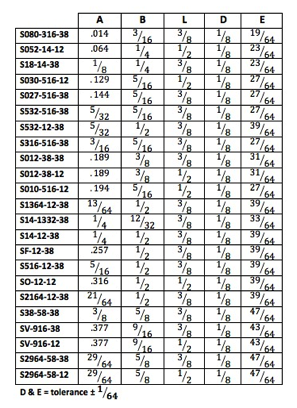

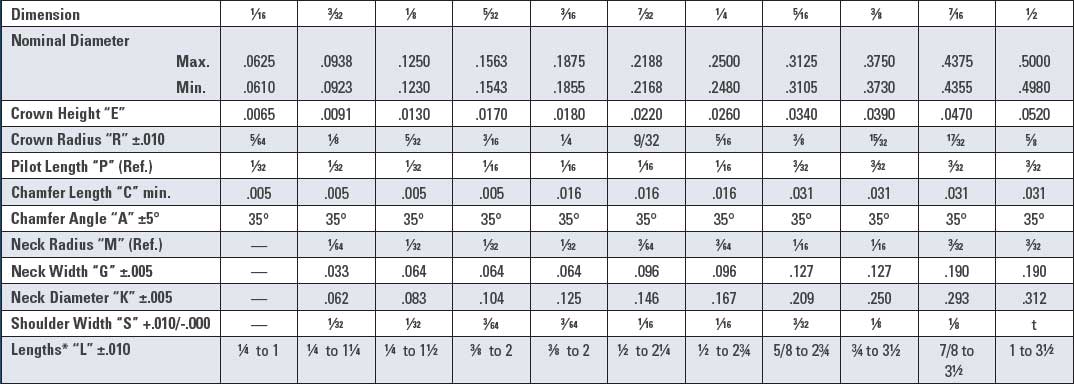

Dowel pin size chart machined asme ansi.