Interference Fit Tolerance Chart

Class v locational interferance fit tolerance chart for holes and bolts per mcdonald douglas design guide machining tolerances.

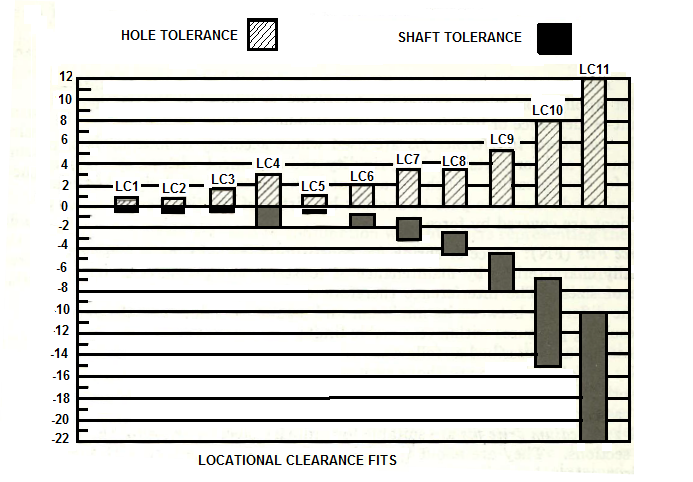

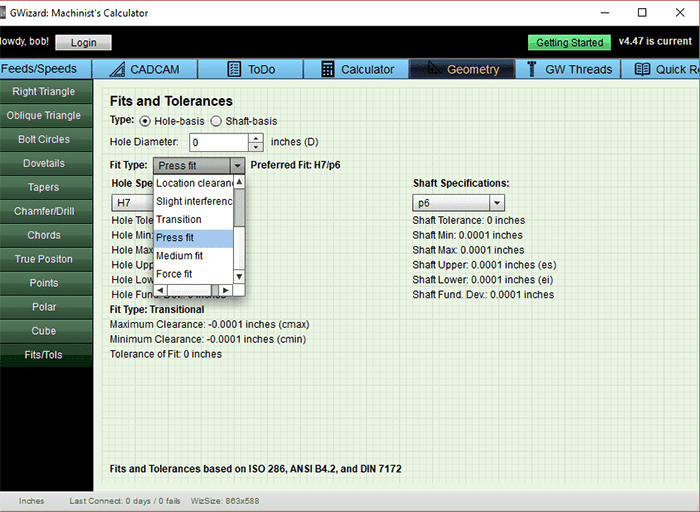

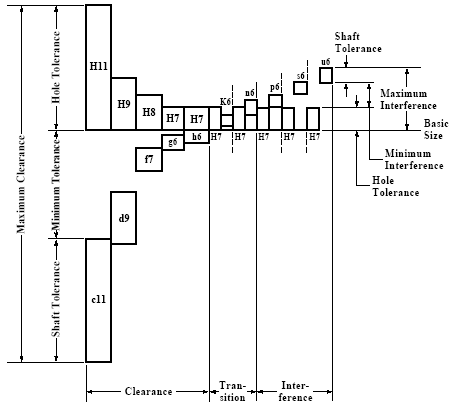

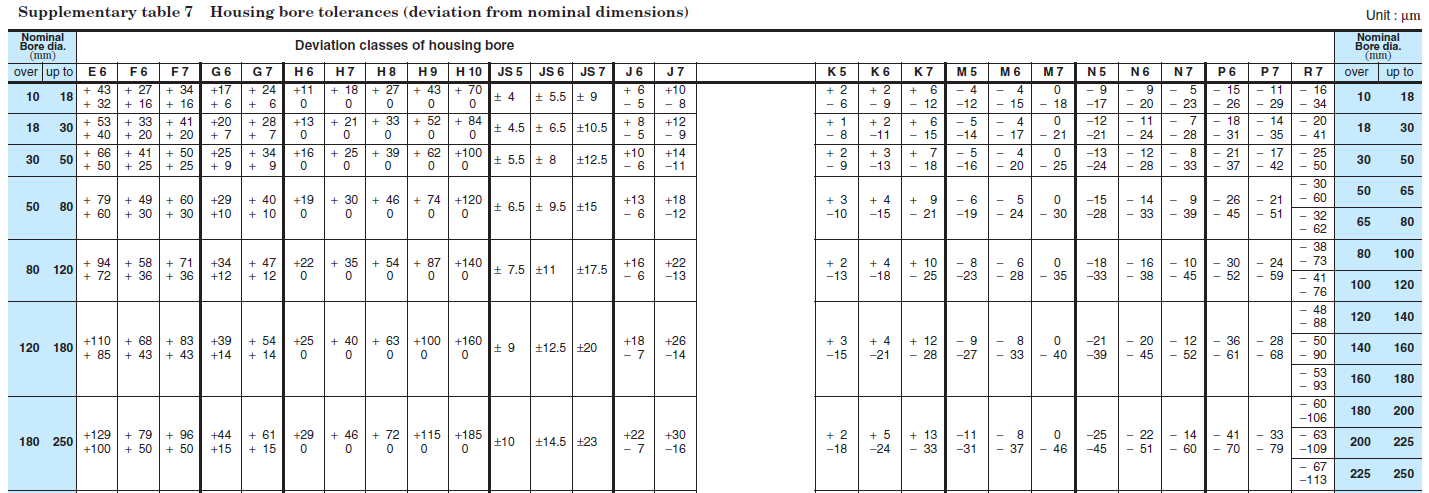

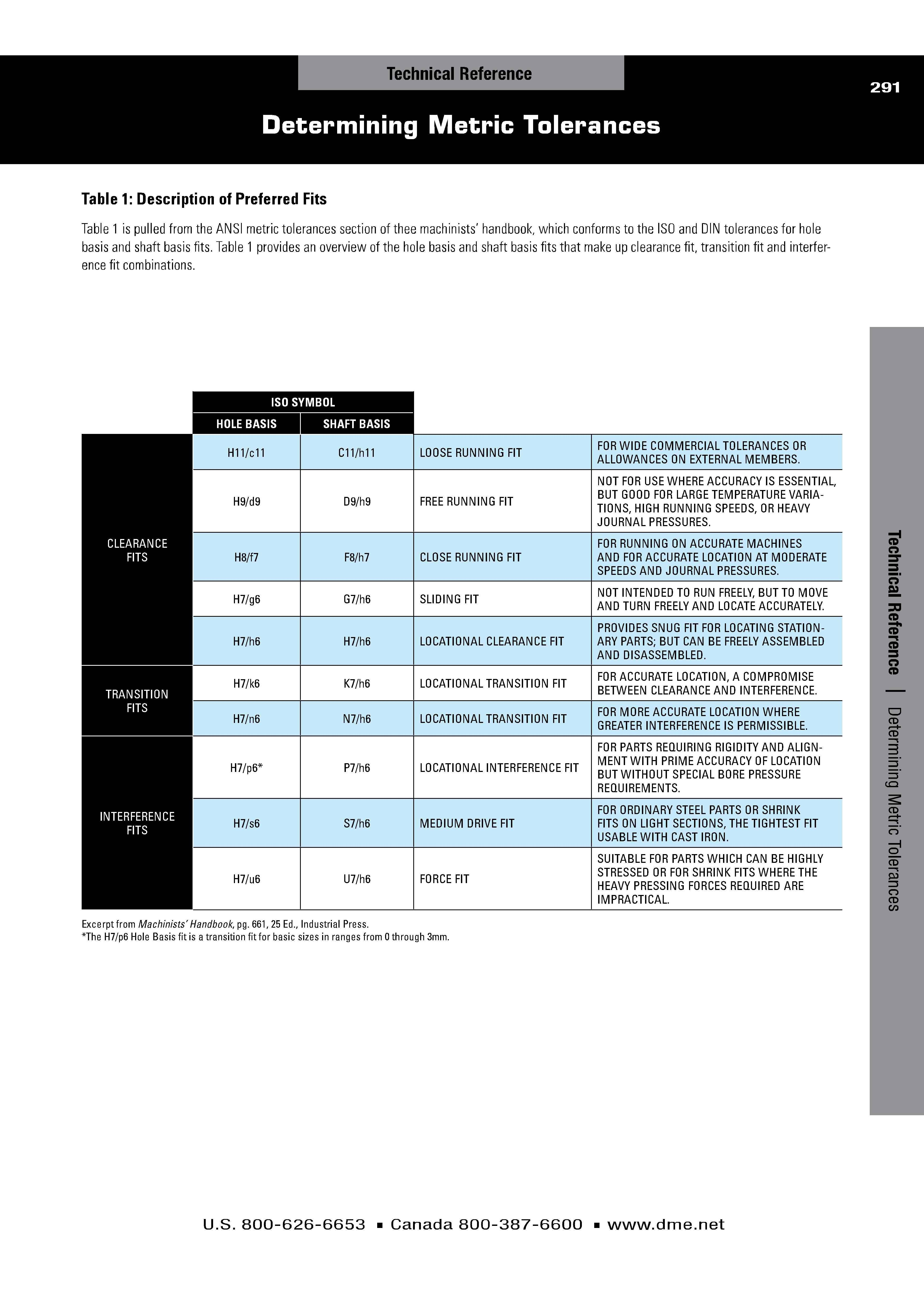

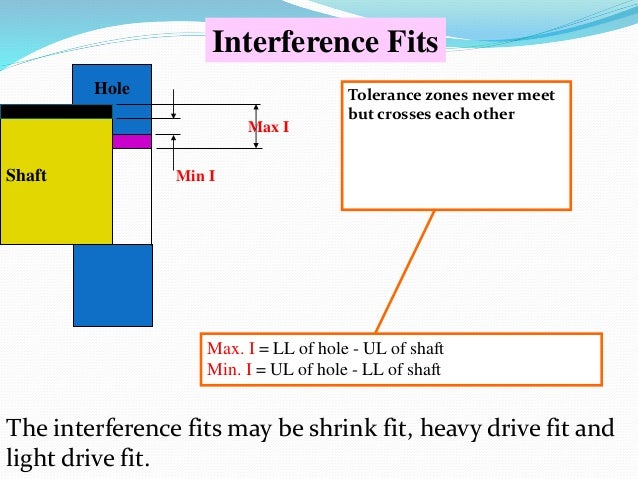

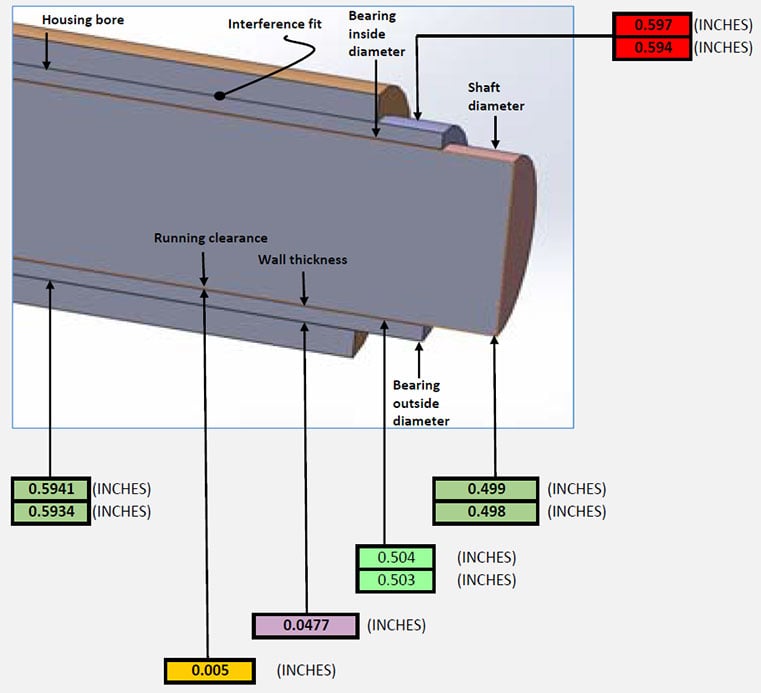

Interference fit tolerance chart. Locational interference fits are used where accuracy of location is of prime importance and for parts requiring rigidity and alignment with no special requirements for bore pressure. The following links are to general tolerance table charts for standard shaft hole fits per mcdonald douglas design guide machining tolerances. Fits and tolerance calculator for shaft and hole according to iso 286 1 and ansi b4 2 metric standards. The schematic representation of the fit is also drawn.

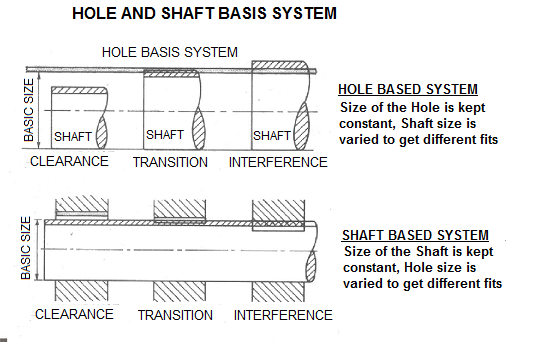

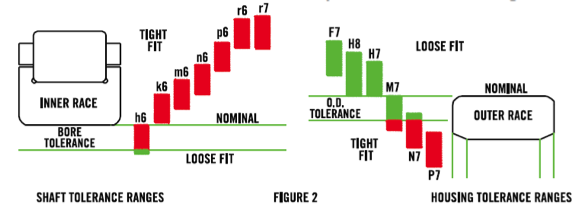

Multiple fits of shafts of production and piston machines parts rotating very rarely or only swinging. Conversely an interference fit is a fit where there will always be overlap in the joint between the specified mating shaft hole even at the minimum material condition values allowed by the shaft and maximum value allowed by the hole tolerance values i e the largest hole and the smallest shaft. Graphical representation of ansi b4 1 1967 locational interference fits table locational interference limits and fits for cylindirical parts ansi b4 1 1967 r1987 all limits shown in chart below are in thousandths of an inches. H9 e9 h8 e8 h7 e7 e9 h9 e8 h8 e8 h7 running fits with greater clearances without any special requirements for fit accuracy main fits of machine tools.

The tolerances defined in iso 286 1 are applicable to size range from 0 mm to 3150 mm but there are exceptional cases defined in the standard which depend on tolerance selection. Are shaft and hole designations used in american british canadian system abc. Mechanical tolerance standards charts geometric boundaries ii gd t reference book. The size ranges given are for typical size ranges utilized within industry.