Copper Press Fittings Vs Solder

The o ring connection in press copper probably a 20 25 year track record in the us.

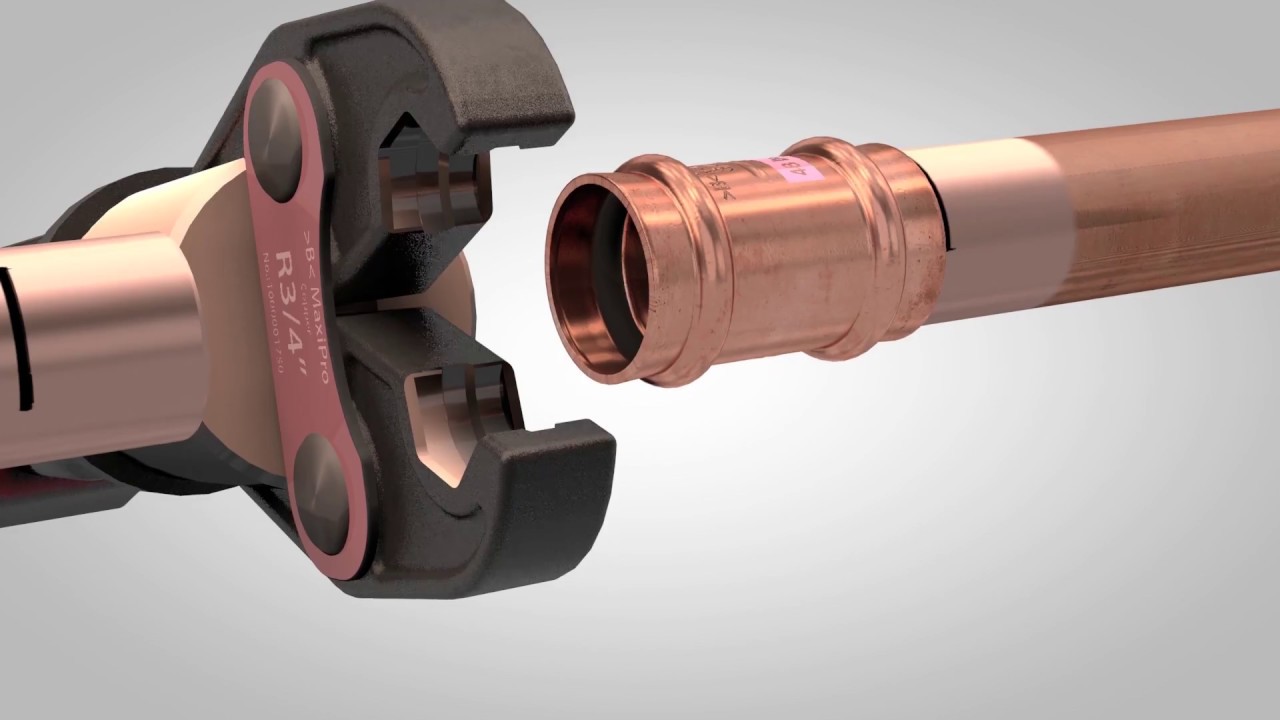

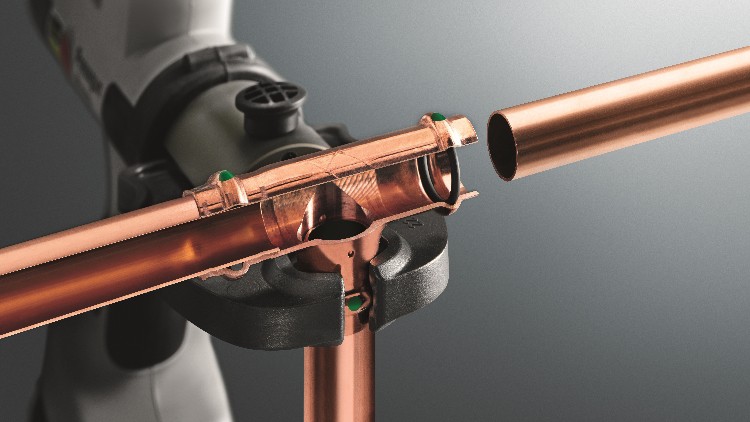

Copper press fittings vs solder. In this system a hydraulic tool is used to press specially designed connectors to join traditional pipes. Solder installation there s are many concerns with soldering on jobsites. Soldering dates back 5000 years or so. Solder installation written by ashley petersen 2016 09 13 as you learned in press fittings and valves vs.

Here s a list of some of the features you could be taking advantage of while using press. Hydraulic press tools crimp joints in copper tubes with press fittings and valves. Although the cost of a press fitting is typically four to five times more than the cost of a traditional copper sweat fitting the savings in labor no cleaning fluxing heating or solder far outweighs the price difference. Egyptians used copper pipe somewhere around 2100 bc.

Copper pipe basics. They can also in most cases be used with either plastic or copper piping. As with soldered joints copper pipes must be deburred before fitting push fits. Sweat fittings have a nonthreaded joint with a diameter slightly larger than the pipe.

About half of the copper used in the united states which would include plumbing pipe and fittings is created from recycled copper according to the copper industry s trade group copper development association inc. The pioneer of press fittings viega s propress fittings have provided a strong alternative to traditional connections since their introduction in 1989 and now see over a million installations a day. They slip onto the pipe then when hot solder is applied the solder seeps into the gap and fuses the fitting to the pipe. Plus significantly less training is required to operate the press tool compared to welding brazing or soldering.

Compression fittings on the other hand have a threaded end with an attached nut. Push fittings can be removed with ease. Here are just a few reasons describing why the press system design makes it a great alternat ive to soldering. These connectors house a sealing element that when pressed creates an even and reliable connection.

Push fit joints are manufactured in both copper and plastic. Press fittings save time and money. This makes press fittings an excellent labor saving solution especially when. With press fittings connections can be made in a fraction of the time that it takes to weld or solder pipe.

I think the 1940 were about when soldered copper became the go to connection. Pex s flexibility is great when you want to go around corners but bad when you need to stub out to a toilet or sink. Available in hundreds of configurations and sizes ranging from to 4 propress fittings are suitable for potable water hot and cold water heating gas solar fire protection and many.